All the models in the HS range can apply labels at a rate of over 3000/min or 200,000 labels/hour dependent on label length.

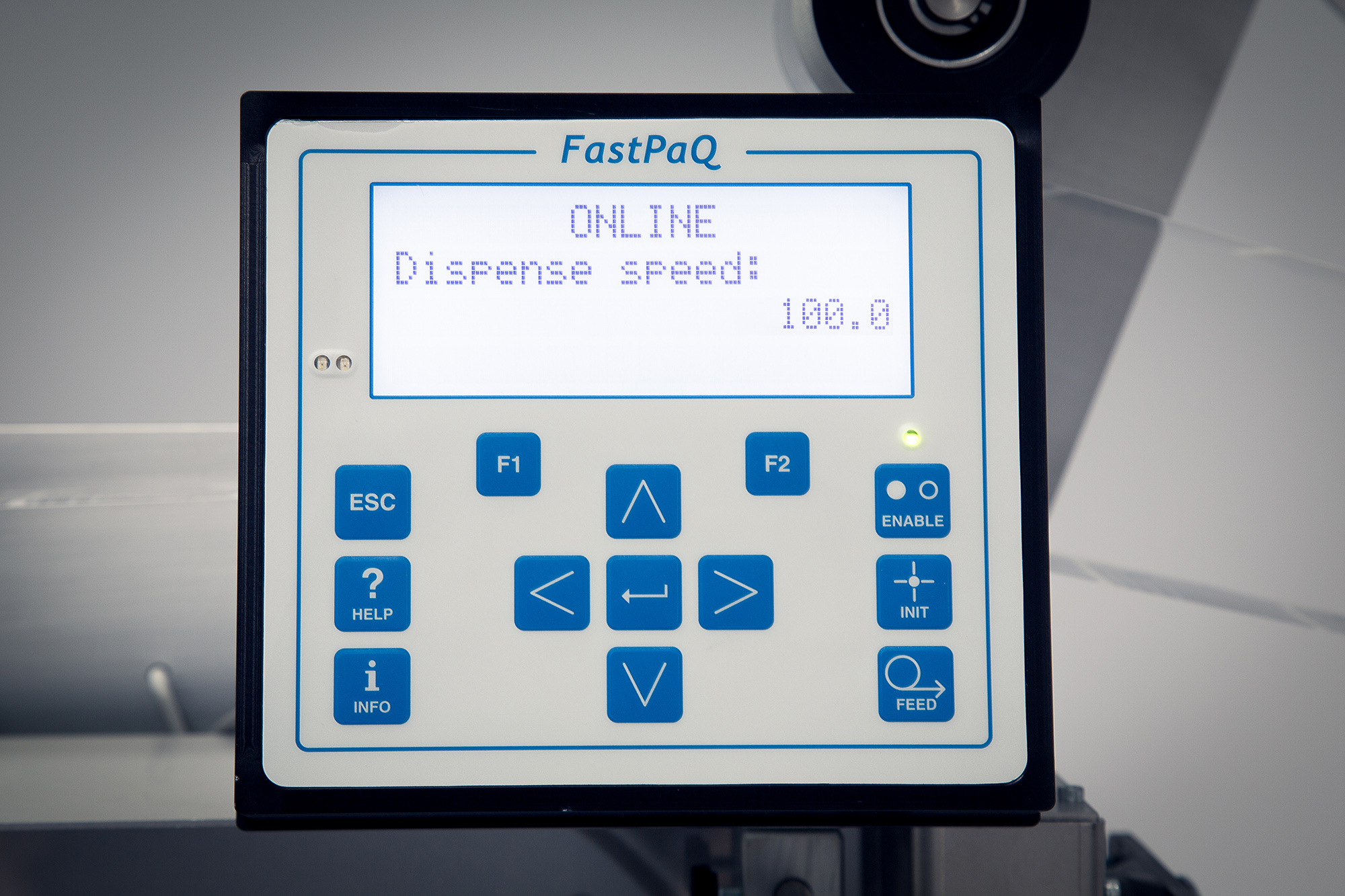

The VHS (Very High Speed) labeller has a maximum dispense speed of 100m/min, 150m/min (via software upgrade) or 200m/min (via software and hardware upgrade)

The UHS (Ultra High Speed) labeller has a maximum dispense speed of 250m/min, 300m/min (via software upgrade) or 375m/min (15,000″/min) (via software upgrade)

Not only are the HS series labellers fast, they are also very accurate, with *placement* accuracy of +/- 0.4mm (+/- 1/64″). This level of placement accuracy is maintained even when the line ramps from stand-still to production speed and back again so with the HS series labellers there is no reject product through inaccurate labelling everytime the production line is stopped or started.

The HS labellers consist of up to four individual modules. If used with fan-fold labels and a vacuum take-away for the waste backing material then only the dispense unit and the loop unit are required.

The loop-box unit provides a zero-tension supply of labels to the dispense unit. The two units can be joined together together to form a single compact labelling machine but where space is very limited the two units can be separated and operated as even more compact stand-alone units. When the fan-fold labels can be located very close to the dispense unit then the loop-box unit is not required.

If utilising rolls of labels then the unwind unit is required. The unwind unit can be attached to the loop-unit or it can be located remotely when space is limited.

The waste backing material can be removed using the optional rewind unit.  The rewind unit is normally attached to the loop-unit but can also be located remotely when space is limited. Alternatively the waste backing material can be removed with a vacuum take-away. Narrow backing material can even be removed with a vacuum take-away unit integrated into the dispense unit itself.

The rewind unit is normally attached to the loop-unit but can also be located remotely when space is limited. Alternatively the waste backing material can be removed with a vacuum take-away. Narrow backing material can even be removed with a vacuum take-away unit integrated into the dispense unit itself.

All the HS series labellers have a common user interface and most of the mechanical and electrical components are common to all models meaning one model can quickly and easily be upgraded to the next model in the range should requirements demand it.